Reduced Downtime, increased production of pumps & associated plumbing

Lower maintenance & operation expenditure

Lengthen lifespan of asset integrity

Greatly reducing time & environmental impact of decommissioning

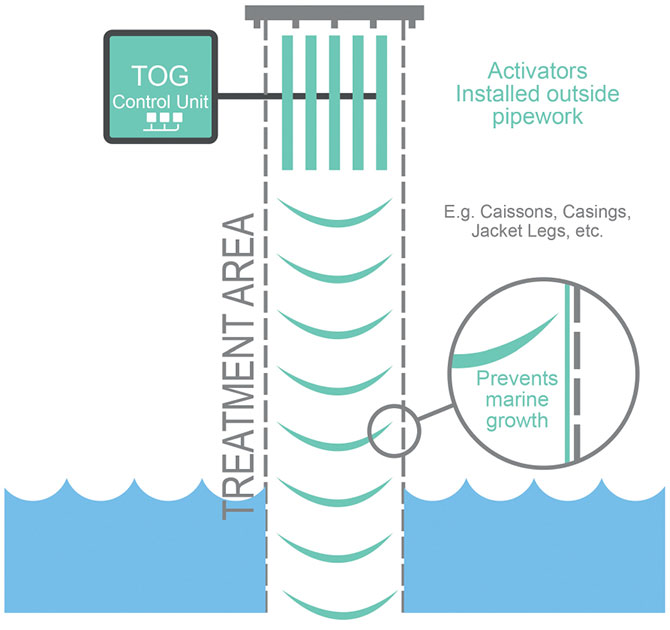

Telfer Tech Oil & Gas System (TOG) is the marine arm of AntiBio. It is an innovative environmentally friendly technology which acts as a preventative solution for marine fouling on offshore platforms, including caissons, conductors, casings, jackets legs and numerous other structures.

At the heart of the TOG System is the AntiBio Technologies proprietary SSF technology specially packaged and hardened for implementation in the harshest marine environments.

Telfer Tech TOG System uses low frequency sound (5kHz & lower) to treat particle matters like microorganisms in flowing fluid, biofilm and calcareous growth. Each TOG system consists of a Control Unit (“Controller”) that is scalable depending on site requirement and Activators.

The Controller is powered by a low voltage power pack (10VAC 1 AMP) that houses a circuit board incorporating a pre-programmed microchip that is configured to transmits more than 10 million sets of sonic waves at preset intervals. The sound emitted creates Sweeping Sound Frequencies (“SSF”) patterns and is propagated to the areas of treatment through the activators.

AntiBio Control Unit

AntiBio Control Unit

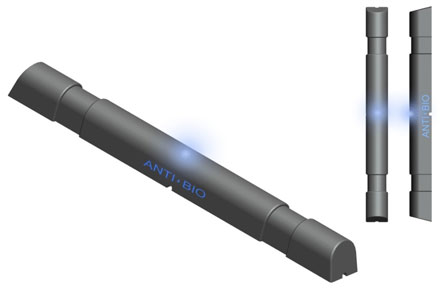

AntiBio Activators

AntiBio Activators

The activators are made of ferrite rods wrapped in heat-shrink and covered in protective shield casings. The typical dimensions of each activator are 200mm in length and 9.5mm in diameter.

Activators are mounted on the external side of the structure to be treated or protected. Usually the location where the Activators are installed is at the center deck and above water.

Installation of the TOG System is simple and straight forward and can be Online installed (no need to shutdown) in most cases.

How does it work

It has been shown that Telfer Tech’s patented Sweeping Sound Frequency (“SSF”) Technology effectively reduces particle reproduction and retards habitual function of microorganisms in the areas that are shielded with SSF.

The shielded area is a STRESSFUL environment for living microorganisms and is detrimental to their survival and reproduction of cells. Microorganisms in the shielded environment are neither able to carry out normal metabolic growth processes or feed properly, they become week and find it difficult to reproduce. The weakened microorganisms will also lose their attachment to the structure and break away, and over time their population will diminish.

TOG’s SSF Technology emits over 10 million sets of variable sound frequencies that spread into surrounding media that rupture microorganism cell walls. The sweeping sound ranges comprise alternating low frequencies and modulations that disrupt cell membrane structure for increased permeability leading to rupture. The algorithms used for emitting the range of frequencies prevent cell immunity and adaptions and ensure maximum cell wall rupture on a continuous basis for eradication of microorganism populations.

Generally, there are two forms of marine fouling: micro fouling and macro fouling.

Micro fouling relates to the formation of Biofilm and often this is the first layer of fouling notwithstanding any form of human intervention or surface protection. Biofilm formations is a process where microorganisms produce extracellular polymers that facilitate attachment and matrix formation and universally grow on surfaces.

Macro fouling relates to growth of barnacles, worms, other forms of calcareous growth and hydrozoa.

Micro fouling in most cases is the precursor to macro fouling where the later develops into uncontrollable colonies. BIOFILM is the culprit and ROOT CAUSE of virtually all problems related to marine fouling.

Over many years of product development, pilot demonstration projects and commercial installations, TERFERTECH SDN BHD has successfully treated and validated its TOG SYSTEM for effectiveness and consistency in dislodging and preventing growth of biofilm on sea structures and pipe-works.